Dog Chews Extruding Machine For Making Kibbles

The description of our machine:

The use of pet food extrusion equipment in the pet supplies

industry is widespread and established, mainly due to the following

benefits of the production process:

- Fast - Pet food extruders operate continuously, yielding high

quantity to meet strict production deadlines. Diamond America

extruders are designed for fast, easy changeover and cleaning

between runs.

- Flexible – Extrusion pet food manufacturing is adaptable, for

application to a wide range of input material types. Also,

extrusion can produce many different forms of final product in

terms of shape, texture and color.

- Consistent - Pet food extrusion and cutting produces a very uniform

end product of constant cross section and size. The process is

extremely controllable and reliable, allowing high quality to be

maintained throughout.

- Efficient - The highly repeatable extrusion process is low in cost,

especially once conditions have been optimized. Precise process

control and automation reduces waste and boosts productivity.

Pet food extrusion equipment can be used on all forms of

manufactured feed: dry food (sometimes called kibble), semi-moist

products and treats. Common pet food ingredients include flour,

meal, grits, meat, fats, minerals, amino acids and vitamins, often

with the addition of flavor enhancers, texturing agents and

preservatives.

The growing industry dictates frequent product changes, both in

ingredients and aesthetics, to suit market trends and demands. The

adaptability of pet food extrusion equipment easily accommodates

process innovation and variation, without significant changes in

machine configuration.

1.Working principle: Pet food is plant or animal material intended

for consumption by dogs or other canines. In extruder, the

ingredients are cooked under intense heat and pressure as it moves

toward the open end of the extruder where ingredients pass through

a shaping die.

2. Different shapes can be made by adjusting the dies from extruder

3. Output can be 150kg/h, 260kg/h, 500kg/h, 1000kg/h

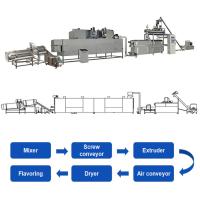

4. Flow chart:Mixing system---Extrusion system----Drying

system----Flavoring system--Packing system

5.Raw material: corn flour, wheat flour, wheat bran, soy meal, meat

& bone powder, animal fat, vegetable powder, salt, water

6. Voltage in China: Three phases: 380V/50Hz, Single phase:

220V/50Hz, we can make it according to customers' Local voltage

7. All the machines are made by stainless steel, this line is with

reasonable design and with high automation; the screws are made

by alloysteel, with building block system structure and

self-cleaning function

Raw Materials: Adopts soya meal, fish meal, bone meal, rice bran etc. As raw

materials.

Dog Kibble Food Machine Flow Of Chart:

mixer→screw conveyor→twin screw

extruder→air

conveyor→dryer→hoister→flavoring drum

and oil sprayer→cooling machine→packing machine.

Mold and samples:

Technicial Parameter

| Model | DR-65 | DR-70 | DR-85 | DR-90 |

| Capacity | 120-150kg/hr | 200-300kg/hr | 500-600kg/hr | 800-1000kg/hr |

| Power | 80kw | 90kw | 150kw | 200kw |

| Dimension | 18 x 5 x 3m | 20 x 5 x 3m | 35 x 5 x 3m | 40 x 5 x 3m |

Standard Configuration

| Item | Brand |

| Motor | WEG or Siemens |

| Electric Parts | ABB or Schneider |

| PLC and Touch Screen | Siemens (controls whole line, not one or two single equipment) |

| Bearing | NSK |

| Materials | cover body, mesh belt and parts touching with raw materials or

final products are stainless steel |

Dog Kibble Food Machine Machine Features:

1.high capacity and Long service life

2.The cutting structure is very advanced. It has such outstanding

features as novel design,

unique, simple structure,easy to installation and unloading, easy

operation, etc .

3.There is a special pressure increased device to ensure the

quality and the capacity. Besides,

the Electric heating device improve the feed expansion rate.

4.steam methord floating fish feed pellet machine :Starch

gelatinization can reach 90% to

furtherly increase the feed capacity.

5.The high temperature in the extrusion chamber (max. 160 Celsius)

in accordance with

the needs of customers.

This temperature is necessary to remove the urea of the enzyme in

soybeans, extending

the shelf life of rice bran, cotton seed or detoxification.

6.The fish feed pellets can float in water for about 24 hours. It

is very catering and easy to

be digested for animals, especially fish.

We Provide Satisfied service and Turnkey Solution

A. Free consultation service before, during, and after sales;

B. Free project planning and design services;

C. Free installation and commissioning of equipment until

everything is functional;

D. Free management of equipments' long distance shipping;

E. Free training of equipment maintenance and operating personally;

F. Free new production techniques and formulas;

G. Provide 1 year complete warrantee and life-time maintenance

service;

H. Engineers available to service machinery overseas.

I. Provide technical exchanging

A. Finished time

The production line will be finished in 25-40 days after

confirmation.

B. Payment Term

30% is paid by T/T as the down payment, 70% is paid by T/T or L/C

before shipment.

C. Delivery Time

When the machines are finished, we will invite you to our factory

for testing machine.

then we will arrange the worker to load container promptly after

all corresponding inspection issues finished.

Video:

Smart plant:

Videos link for pet food production line:

Any interest, please be free to contact us!

smart2@smartmachinery.cn

Whatsapp/wechat: +86 15153189382