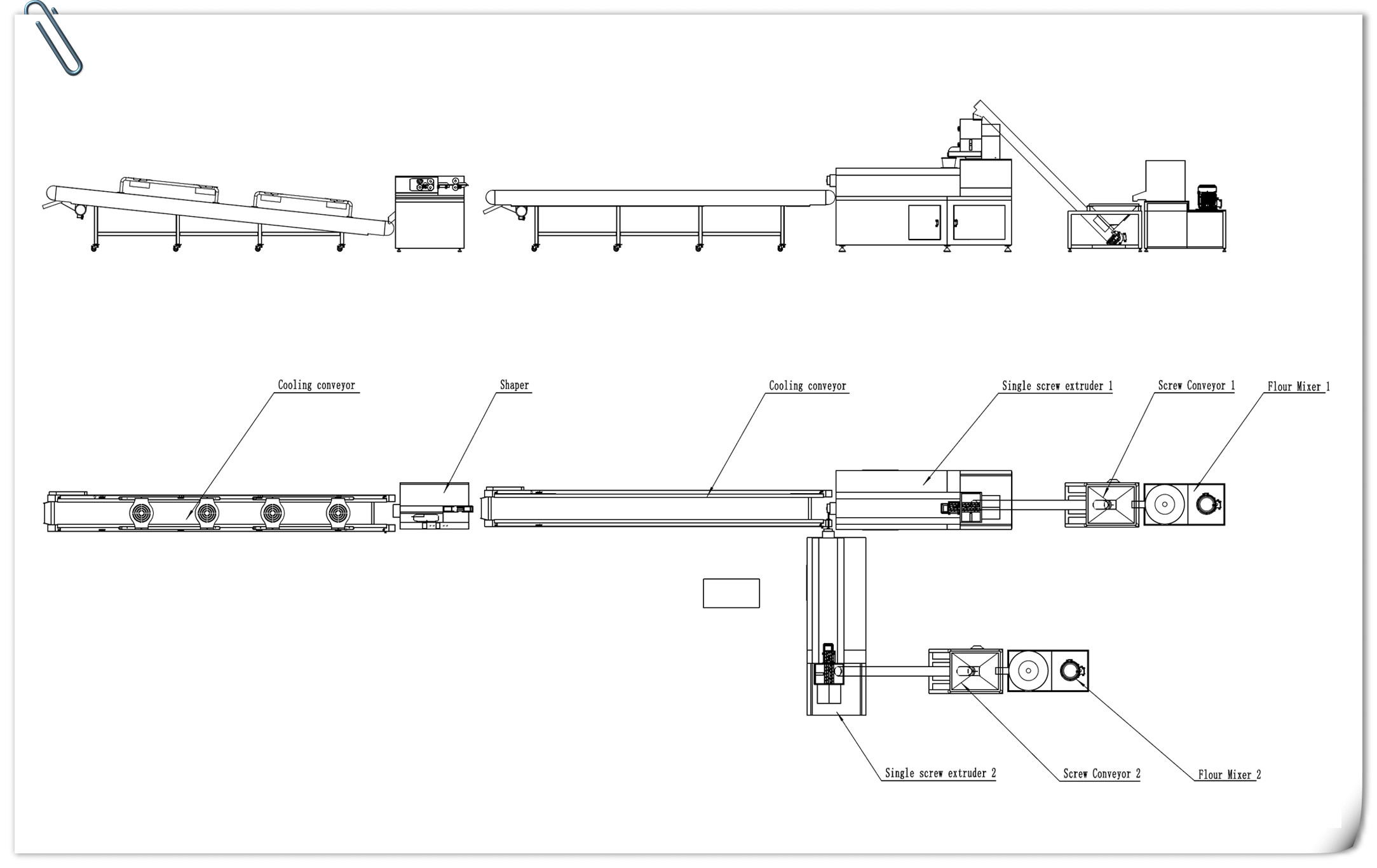

Flour Mixer

Output: 60kg/load Power: 4kw/380V Dimension: 1200 x 800 x 1200mm Weight: 230kg | Flour Mixer is used to mix the raw material, like corn flour, rice

flour, fish bone flour, ox bone flour with liquid and other

additives.

- Stainless steel structure, especially the parts in contacting with

the raw material or products;

- Cover small area, easy cleaning, and operate stably.

|  |

SRD-300 Single Screw Extruder

Output: 150kg/hr Extruder Dimension: 3450 x 900 x 2200mm

Feeding System: Feeding power: 0.75kw Feeding screw diameter: 55mm Feed Screw Speed: 0-150rpm

Driving & Extruding System: Main Motor Power: 45kw Main Screw Length: 3250mm Main Screw Diameter: 100mm Main Screw Speed: 0-250rpm Heating Zone: 5 zone Heating Power: 2kw x 7 = 14kw (7 heating rings)

Control System: Electric Cabinet Dimension: 630 x 470 x 1740mm

| SRD-300 Single Screw Extruder serves to gelatinize flours and

starches continuously and automatically. After dosing, the

materials are worked by one screw composed by sectional modules for

the following functions: forward and backward transport, mixing,

cooking and forming.

Ø PLC and 10” touch screen with friendly interface to control the

whole line, not one or two single equipment; Ø While any parts got problems, the fault alarm will be shown on

the touch screen; Ø Password can be set on the touch screen to avoid any misoperation

by the workers; Ø The structure is made by carbon steel, and the cover body, mixing

tank and all the parts in contacting with the raw material are made

by stainless steel; Ø A wide range of products can be obtained in a variety of

different ways, and can configure various dies simply and rapidly; Ø Two sets of Single Screw Extruder can work together to make

double-color pet treats, also can connect Twisting Device for twist

pet treats; Ø The use of a continuous automatic process provides greater

production outputs than offered by traditional systems, with

savings in energy and reduced management cost; Ø The screw is all made by 38CrMoALA alloy, and the surface is

being processed nitrogen treatment, so the hardness could reach

55hrc, which is hard and strong, and has longer service life; Ø Barrel is divided into 4 temperature zones, and each zone is

controlled separately; Ø Auto-temperature control system; make the temperature controlling

more direct viewing and the parameter more precise; Ø Equipped wit cooling system for cooling the barrel and screw; Ø Control cabinet has three kinds of protections: overload

protection, overcurrent protection and overheat protection. Ø Nice appearance with streamline modelling. |

|