Shandong Smart Machinery Co., Ltd is a professional food machinery

manufacturer since 2004 located in Jinan, China.

Now, about 80% of our products export to foreign markets, including

Southeast Asia,Middle East, Africa, Europe, North America, Central

And South America and so on. In addition, Smart establish good

coopration with customers cover more than 60 countries.

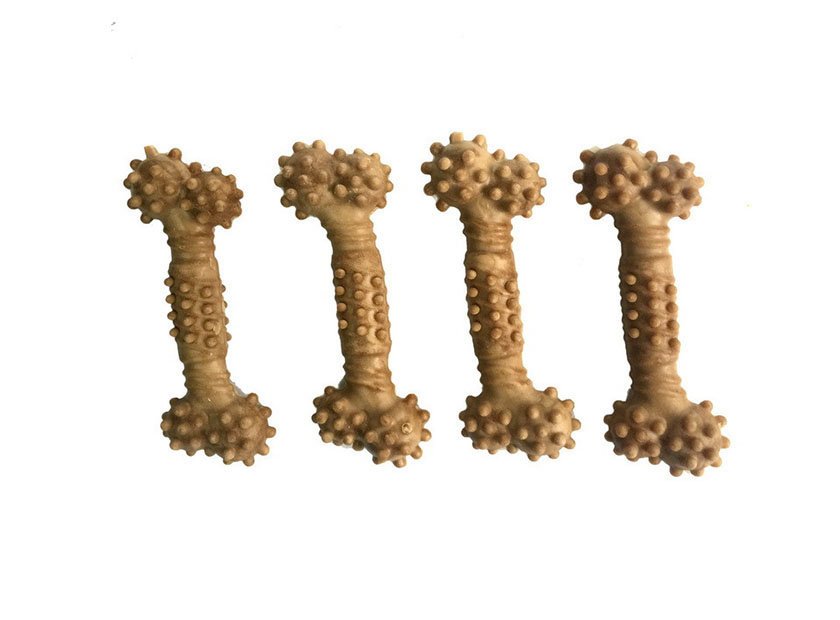

Smart specialize in providing human food machine and pet food

machine, our hot sale production machine line are cereal bar making

machine, puff snack extruding machine, corn flakes/cereals

production line, pet treats and pet food making machine.

Smart considers credit and quality vital to our life coupled with

outstanding technology.

Relying on our own R&D advantages, can supply customer OEM

service,and do machine design & test for free.

Welcome to contact us and achieve mutual beneficial cooperation.

The main products includes:

Smart considers credit and quality vital to our life coupled with

outstanding technology. Our machines are now running in many

countries and gaining more and more customers due to its reliable

and optimal performance 24 hours round the clock service ⏰

You’re welcomed to contact Smart and we trust that your cooperation

with Smart will be mutually beneficial to both sides!